Overview

Boiler tubes work under harsh environment. Inside, high pressure steam & water runs through. Outside, boiler tubes are exposed to flue gas at elevated temperature. Boiler tube leak is common issue for safe and continuous operation in long term. Online monitoring for tube leak in real-time could give operators alert at an early stage. Detection system by acoustic emission technology can avoid unplanned outage, mitigate secondary damage and reduce downtime. So boiler tube leak detection is of great significance to keep power plant assets on top of its condition.

What causes boiler tube leak & failure?

There are many things that can cause tube leak & failure.

- Weld defects such as pinhole, slag inclusion, insufficient penetration, etc.

- Abrasion by fly ash, CFB boiler circulating sand & coal lump, hangers & supports.

- Pitting corrosion, stress corrosion, high temperature corrosion, corrosion by oxygen, acid, HCL gas, NOX, etc.

- Thermal stress rupture.

- Over temperature operation.

What happens when a boiler tube leaks?

A tiny tube leak that goes undetected could turn into tube failure. It could result in serious damage, unscheduled shutdown and expensive maintenance. Such accidents are dangerous, hazardous and costly for economic operation of facility.

How to detect boiler tube leakage?

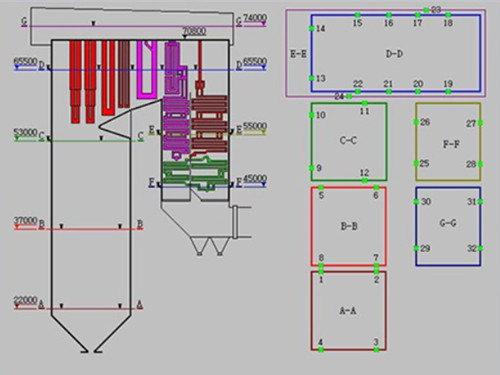

Tube leak detection system is developed based on acoustic emission technology. During normal operation, you can hear background noise when walking around boiler. However, when leakage occurs, some abnormal noise will be generated due to high pressure steam or water jet from boiler tube. Frequency curve and sound levle of this noise is different from that of background noise. Acoustic sensors mounted on furnace wall and flue pass collect sound signal and convert into analog signal, which is then transferred into frequency spectrum by Fast Fourier Transform technology and shows on computer screen. Acoustic monitoring and detection system will tell it is tube leak or not on the base of difference between sound level at specific frequency. Our highly sensitive system could even find out small leaks of 1mm and identify its location.