Boiler tube leak detection system

Product Details

Overview

In modern plants, supercritical and ultra-supercritical units with high capacity 300MW, 600MW are common for thermal power generation. Inside, high pressure steam & water runs through boiler tube. Outside, boiler tubes are exposed to flue gas at elevated temperature. Boiler tube leak is great concern for safe and continous running in long term. It could leak to unscheduled shutdown and expensive damage if the situation goes undetected in long period. Such accidents are dangerous, hazardous and costly for economic operation of facility. Online monitoring for tube leak in real-time could give operators alert at an early stage. Detection system by acoustic emission technology can avoid unplanned outage, mitigate secondary damage and reduce downtime. So tube leak detection is of great significance to keep power plant assets on top of its condition.

Application

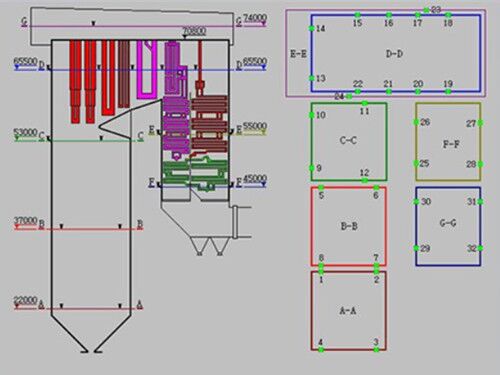

Whether CFB boiler, pulverized coal fired boiler or heat recovery steam generator (HRSG), tube leak detection system could bring tubes of furnace waterwall, superheater, reheater, economizer under monitoring. Our leading technology enables plants to find and locate early tube leaks, then take actions before intensive damage.

Principle

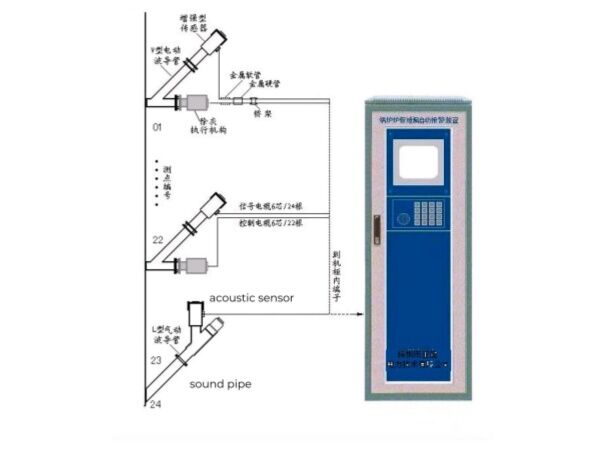

Tube leak detection system is developed based on acoustic emission technology. During normal operation, you can hear backgroud noise when walking around boiler. However, when leakage occurs, some abnormal noise will be generated due to high pressure steam or water jet from boiler tube. Frequency curve and sound levle of this noise is different from that of background noise. Acoustic sensors mounted on furnace wall and flue pass collect sound signal and convert into analog signal, which is then transfered into frequency spectrum by Fast Fourier Transform technology and shows computer screen. Acoustic monitoring and detection system will tell it is tube leak or not on the base of difference between sound level at specific frequency. Our highly sensitive system could even find out small leaks of 1mm and identify its location.

Benefits

- Tiny leaks, which can’t be heard by patrol people at site, can be detected to avoid massive loss. It brings asset and personnel safety to a higher level.

- Real-time and constant monitoring on leakage condition puts operator on informed position to make optimal decision.

- Quick location allows less time spent on looking for leaks and more time on planned shutdown.

- Early detection can reduce plant downtime and repair expense.

- Minimize secondary damage to neighboring tubes.

Function

- In-time detection and early alert to maximize production and revenue of power plant.

- Tell the location of tube leaks without sending people to hard-to-access areas

- Follow up on leakage condition and trend.

- Automatic alarm and display of leakage location.

- Show frequency spectrum of sound wave and display in bar chart on computer screen.

- Allow monitoring on working status of soot blower. Is steam pressure abnormal? Does lance tube rotate normally? Whether lance tube gets jammed? You will have answers for these questions with acoustic leak detection system.

- Interface with DCS and telecommunication to achieve remote monitoring, diagnosis and maintenance.

- Acoustic data can be stored for 12 months. Data printing and query is available.

Online monitoring and detection for boiler tube leaks is worthy for modern power plants. Financial savings created by acoustic detection system will be much higher than investment on equipment even at the first event.