Heat transfer element for rotary APH, GGH

Product Details

Heating element function

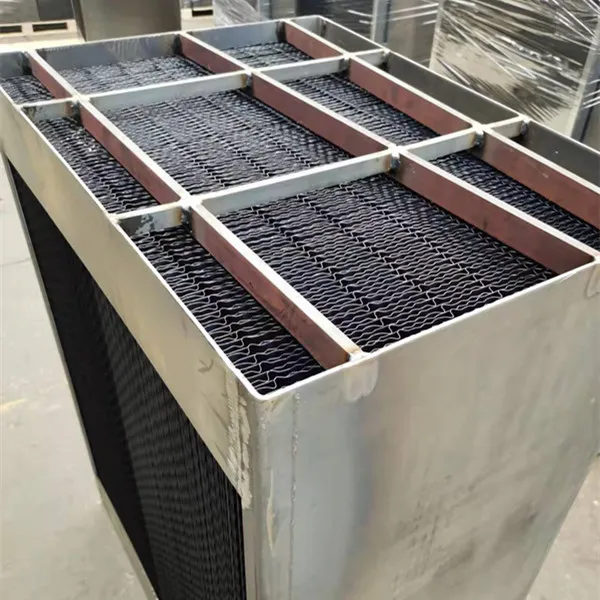

A regenerative rotary heat exchanger is widely used for air preheating (APH) or gas-gas heating (GGH) in thermal power plant. Rotary air preheater improves boiler efficiency by heat transfer from flue gas to combustion air moving in counter-current flow. Heating elements made of cold rolled plate have close relationship with heat transfer performance of APH. Heating elements consist of corrugated plate and positioning plate, which are placed together alternately one by one. And these plates are held in element basket. When rotor rotates slowly at a speed 1-2rpm, heating elements will go through flue gas sector and combustion air sector in sequence. When hot flue gas passes by, heat is transferred to and stored in heating elements. Flue gas leaves from APH at a reduced temperature. When primary and secondary air passes by, thermal energy is released to cold air. Rotor moves continuously, and this cycle goes on and on.

Heating element material

The choice for material of heat transfer element is decided by fuel properties, working temperature, combustion condition, SCR system, etc. For hot end of APH, where temperature is relatively higher, element plate made of carbon steel is good enough. For cold end, enameled element is necessary for the following reason. And materials may be carbon steel, Corten steel, DC04ED, SS409, etc.

Corrosion & fouling problem with rotary APH cold end

Corrosion. When temperature at cold end is lower than dew point, acid vapor turns into liquid form, corrosion happens. It results in rugged surface of heat transfer element, fly ash is easy to build up. Primary & secondary air can’t get expected temperature due to narrowed heating surface.

Fouling. Ammonia escaped from SCR unit would present in APH in the form of NH4HSO4 (ABS), whose melting point is 147℃. Liquid ABS is sticky and easy to attach fly ash. Element fouling mainly occurs in area at 147-207℃, where ABS changes from gas to liquid, then solid state. APH fouling would result in swinging air pressure and higher current of fan.

Advantages of enameled heating element for rotary APH cold end:

- Excellent resistance to acid corrosion.

- Smooth surface, easy cleaning, less deposits.

- Excellent resistance to fly ash erosion. Wearing coefficient of high silicon enamel is 7 times of Corten steel.

- Good chemical stability.

- Thermal shock resistant.

- Parallel heat transfer performance with element made of Corten steel

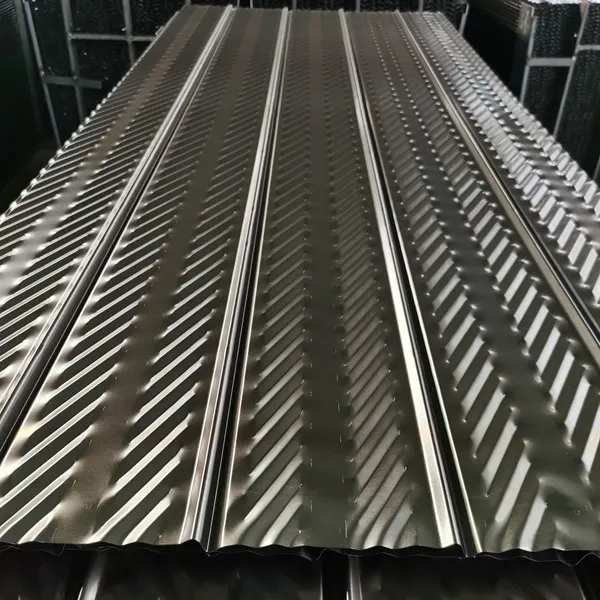

Corrugated plate & Positioning plate

Positioning plate not only acts as heating surface, but also keep gap between corrugated plates to provide proper flow channel. Positioning plate is designed with vertical and inclined corrugation to create turbulence flow. For corrugated plate, there are different options. We could fabricate element profile like double undulated (DU), corrugated undulated (CU), corrugated flat (CF), notched flat (NF), etc. Each profile has different influence on heat transfer, flow resistance and fouling. When making a choice, clients can get professional advice from us.

Heating element supplier

GeckoIntech have automated production line for APH heat transfer element. Electrostatic coating technology could give us product with uniform thickness, homogenous composition, minimum flaw. Enameled element could serve in place no less than 5000 hours. Up to today, we have done more than 50 retrofitting projects for heat transfer elements of rotary air preheater. Their boiler capacity ranges from 135MW to 1000MW. Superior quality and professional service, fast delivery waiting for you. Welcome to contact with us.