Cardox CO2 blasting

Non-explosive Solution for Mining, Excavation and Buildup & Blockage Clearing

Cardox CO₂ blasting system offers a powerful, straight shot solution to clear stubborn rock-hard material without damaging equipment or risking worker safety. It can effectively clear obstacles and remove buildup to restore material flow, optimize processing stream and maintain continuous production.

What Is Cardox Blasting?

Cardox blasting is an advanced, safe, and highly effective method of physical rock breaking technology. It operates as a form of cold explosion, utilizing gas expansion by rapidly heating liquid CO₂ to trigger an instantaneous phase change from liquid to gas. This process generates immense pressure, which is released to fracture rock, concrete or others. Cardox blasting is also used in cement plant to clear buildup and blockage in rotary kiln, preheater, clinker cooler, etc.

How Does Cardox System Work?

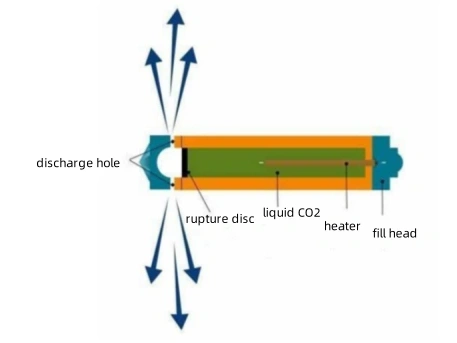

Cardox CO2 system uses a reusable steel tube filled with liquid CO2 and a heater element. When activated by a small electrical charge, heater rapidly converts the liquid CO2 to gas, increasing its volume to 500~600 times and creating high pressure up to 3000bar. This pressure bursts a rupture disc, releasing a high-velocity jet of inert gas that dislodges and breaks up tons of materials.

- Loading – Liquid CO2 is charged into Cardox tube.

- Insertion – CO₂ tube is placed near the blockage.

- Activation – Electrically ignited, safety heater releases massive heat and make CO₂ rapidly expand and build pressure up to 3000bar.

- Blasting – Rupture disc is broken, sudden gas expansion fractures and loosens material.

- Material Dislodged – Gravity pulls fractured material down for smooth flow.

Here is a working video of Cardox system: https://youtube.com/shorts/uYw3EoOBV7s

How Is Cardox Different from Explosives?

Unlike conventional explosives that rely on chemical reactions, Cardox CO2 blasting is fundamentally safe based on physical process of rapid gas expansion. Its key advantages include no open flames, controlled force, simple operation during process, and exemption from government permits typically required for civil explosives in transport, storage and usage. There is no need for magazine and post-blast verification. During expansion, byproduct is simply carbon dioxide gas, no toxic fumes like carbon monoxide and nitrogen oxides.

Can Cardox be Reused? And Working Life of Cardox Tube?

Yes, Cardox tube is made of high strength alloy steel, which makes it tough to withstand high pressure CO2. It can be recharged and reused after each blasting. One Cardox tube can normally serve 1000 times. On the other hand, CO2, shear disc and safety heater are consumables of this system.

Application

Cardox CO2 blasting system provides a safer and more controlled method for breaking down materials and clearing blockages in a wide range of industrial and construction applications, particularly where traditional methods are not suitable due to safety or operational constraints.

- Mining & Quarrying

Cardox is used to break up ores, especially in areas where explosive blasting is risky or prohibited.

- Tunnelling and trenching

Clearing blockages in shafts and tunnels: It helps remove obstructions in shafts, tunnels, trenches and other underground excavations.

- Underwater excavation

Cardox can be used for breaking up rock and concrete underwater.

- Cement industry

Cardox can eliminate rotary kiln rings or buildup in preheater, cyclone, cement silo, feed pipe, etc.

Snowmen at clinker cooler can be removed effectively.

Benefits of Cardox System

- Non-explosive solution, no need for magazine or government permit.

- No flame, open fire or high temperature, suitable with coal mining.

- Online clearing to reduce costly downtime and keep full operation, even in high temperature areas.

- Controlled release of CO2 from directional discharge hole, no damage to silo & hopper structure.

- Safe operation with remote detonator. Labors don’t need to enter hard-to-access area.

- Refillable and reusable Cardox tube makes it economical blasting solution.

- Instantaneous phase transition of inert gas make it safe and non-contaminating.