Steam gas heater

Product Details

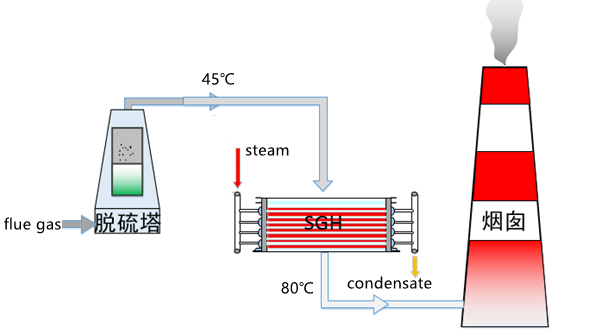

In coal fired power plant, limestone-gypsum process is widely used for flue gas desulfurization. Saturated flue gas by WFGD is corrosive, humid and low temperature. When flue gas is discharged into atmosphere from stack, steam and acid vapor would condensate and form plume. This phenomenon is a result of increased humidity and dew point temperature of flue gas.

Pollutants in flue gas include fly ash, gypsum, dissolved salt, aerosol (SO3), etc. Sometimes, they could cause sour rain and stack corrosion.

Steam gas heater (SGH) is an indirect heat exchanger designed for the heating of flue gas with saturated steam. It could work alone, or together with MGGH, or as heating unit of condensing-reheating system. When steam gas heater is used alone, flue gas is heated to around 80℃, which is a temperature that makes flue gas unsaturated and plume disappear. Although it has no influence on pollutants emission, steam gas heater could improve the diffusion of flue gas by increasing rise of flue gas.

SGH is normally placed between FGD tower and stack. It uses latent heat by phase change of saturated steam (usually below 1MPa) to warm flue gas from 45℃ to 80℃.

Steam gas heater is tubular heat exchanger. Flue gas goes through tube pass, and steam goes through shell pass. To withstand acid corrosion, tubes could use materials like SS2205, 316L, ND steel, fluoroplastic tube or steel tube coating with PTFE.