Gas gas heater

Product Details

Function

Gas gas heater (GGH in short) is a heat exchanger used in power plant to heat treated flue gas (40-50℃) with raw flue gas (130-150℃) in FGD system. GGH plays dual function: flue gas cooling and reheating.

Raw flue gas is cooled down by GGH. If hot flue gas enters FGD tower, it would cause damage to anti-corrosion coating inside FGD tower. And a lower temperature is good for the absorption of SO2.

Treated flue gas is reheated by GGH and leaving at a higher temperature (about 80℃).

Benefits

Enhanced diffusion of contaminants in flue gas.

Better plume abatement performance, higher plume rise from stack.

Less droplets falling down near the stack.

Less corrosion to downstream equipment.

Types

Gas gas heater has many different design:

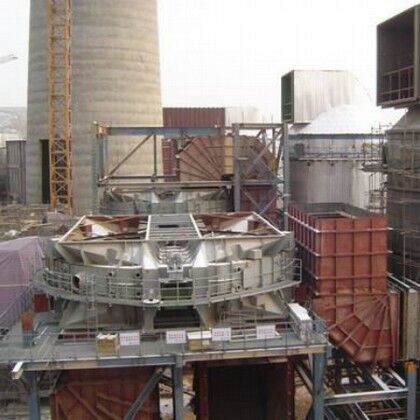

Rotary GGH is counter-flow, regenerative heat exchanger. Heating elements rotate and travel through raw gas passage and treated gas passage alternatively. When hot flue gas passes through rotor, heat is transferred to heating elements, then released to cold treated gas when heating elements move to raw gas passage. It has the similar structure and working principle to rotary APH, but works at a much lower temperature. So, the heating elements must be resistant to dew point corrosion. And to avoid raw flue gas leakage into treated flue gas, it should has a good sealing system and replace entrained flue gas with air to ensure leakage is less than 1.0%.

Heat pipe GGH is an exchanger that uses heat pipe as transfer elements. Heat pipe is enclosed vacuum pipe filled with working medium, which transfers heat by phase change. It is classified into evaporation section, adiabatic section and condensation section. When hot end is heated, liquid medium is vaporized and flows to cold end. Then vapor releases latent heat at cold end and condensates back into liquid, which returns to hot end due to capillary action and gravity. This cycle repeats to transfer heat from hot temperature fluid to low temperature fluid.

As hot/cold fluids are separated by partition board in heat pipe GGH, there is no need to worry about leakage. Due to heat pipe has a much higher heat transfer ability than steel tubes, so heat pipe GGH could be built in a much smaller size to achieve the same purpose. And it has good transfer ability under low temperature difference.

Tubular GGH could use enameled steel tube, glass tube, fluoroplastic tube as heat transfer element to solve corrosion problem under low temperature.

flue gas heat exchanger made all by fluoroplastic

Plate type GGH could use stainless steel, cast iron or silicon carbide to extend service life.

Gas gas heater would increase pressure loss in flue gas system, fuel consumption of FGD system and operation cost, it is not so popular for power plant fired by fossil or biomass fuels. But for waste incineration plant, it is still important.