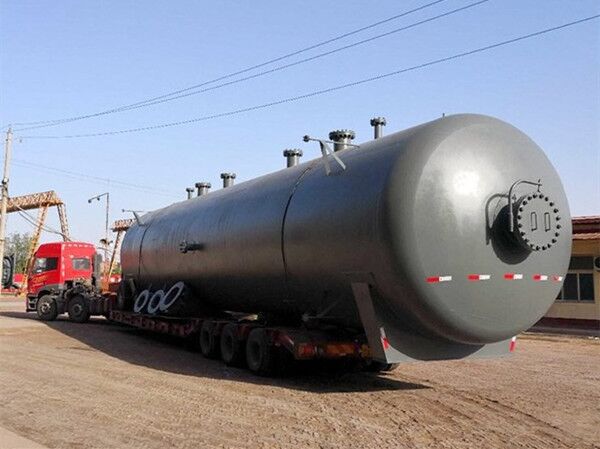

Steam accumulator

Product Details

Application

Steam accumulator is a buffer tank to store excessive steam produced by boiler. In some industrial applications, steam consumption is up and down. It is not an economical and quickly responsive way to adjust the boiler load along with variable steam demand. As boiler capacity is higher than the average consumption, it is necessary to have a suitable steam accumulator to store the excessive steam. Here steam accumulator plays as buffer tank. It receives steam when demand is lower than boiler capacity, and release steam when demand is higher than boiler capacity.

Working principle

Inside accumulator tank, downside is 65 ~85% soft water, above is the space for storage of steam. When steam load is low, steam from boiler is injected into water. Steam will condensate and release heat. Temperature & level & saturation pressure of water will rise. Heat content of water is increased. This is called charging process. Hot and pressurized steam is stored in liquid form as a reserve for peak demand.

If steam load is higher than boiler capacity, pressure in steam network goes down. When it is lower than saturation pressure inside steam accumulator, saturated water will become overheated water. Part of water will flash into steam to keep stable supply. Temperature & level & saturation pressure of water will decline. Heat content of water is decreased. This is called discharging process.

Steam accumulator is designed to smooth out the fluctuation in steam consumption. With it, a smaller boiler is possible to provide stable steam supply. It is widely used in industries like brewery, textile, steel, dry cleaning, autoclaves, etc. We provide customized solution to meet with specific requirement.