Mechanical rapping system

Product Details

Application

For thermal power plant, soot accumulated on heating surface would cause big problems. It would reduce boiler thermal efficiency, increase fuel consumption. Sometimes, unscheduled shutdown occurs, because flue pass is blocked and tube failure happens. There are many different ways for boiler cleaning, such as steam soot blower, sonic horn, pneumatic pulse cleaning, shock wave cleaning. Mechanical boiler rapping system by tumbling hammers is widely used for waste heat boiler (especially for SP boiler in cement plant), biomass boiler, MSW boiler, etc.

Advantages

Mechanical rapping system could clean soot deposits on platen heating surfaces and tube bundles without need for medium like steam, compressed air, etc.

Working principle

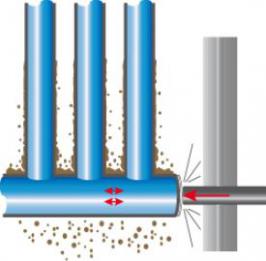

Rapping hammers are connected to a rotating shaft driven by motor and gear unit. When the hammers are lifted, they gain potential energy, which is transferred into great impact energy when falling hammers collide with a beam. The force applied to beam will cause vibration of tube bundles, and shake off soot build-up. Weight and mounting arm length is closely related with impact force.

Benefits

- Keep a clean heating surface on boiler superheater, evaporator, enonomizer.

- Improve boiler efficiency, reduce flue gas exit temperature.

- No air, water or steam is used as cleaning medium. It brings lower operation cost.

- Automatic stop when hammers are stuck to avoid damage of rapping system.

- Precise fabrication & rigid structure gives boiler rapping system a long service life.

We are famous mechanical rapper manufacturer in China. Leading design and reliable performance brings us reputation. Now we are approved vendor for many waste heat boiler manufacturers.