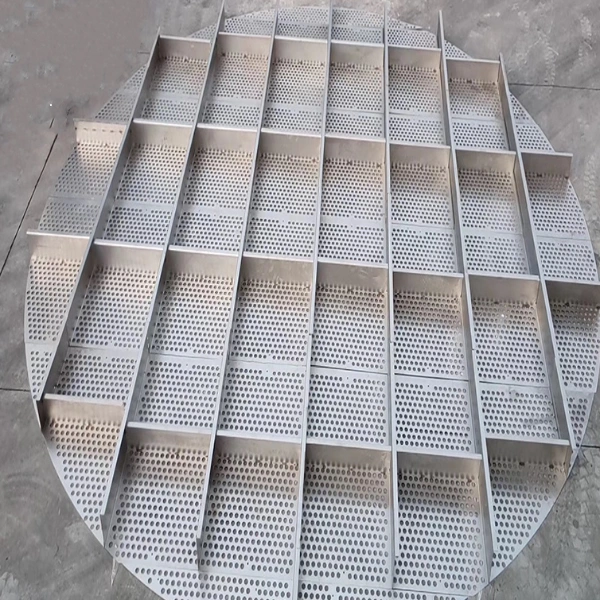

FGD scrubber sieve tray

Product Details

Introduction

Flue gas desulfurization by wet absorption is proven and popular technology for decades. Chemical reaction between gas/liquid phase transfers SO2 to CaSO4 finally. One key factor that influences SO2 removal performance is adequate contact between flue gas and limestone slurry. Gas distribution tray is installed to upgrade FGD spray tower to higher efficiency.

Principle

Sieve tray is suggested to create uniform gas/liquid distribution on cross section of spray tower to meet with stringent emission policy. When there is a maldistribution, contact between rising gas and falling liquid is uneven. This brings the result that some of flue gas is overscrubbed and some of flue gas is underscrubbed. Below is a picture that illustrates difference with/without gas distribution tray.

Fabrication material

FGD scrubber tray works in corrosive and hot environment. There are different materials for choice.

- SS304 working temperature to 400℃.

- 316L working temperature 600℃.

- 2205, working temperature 600℃, applicable pH range 4-9.

- 2507, working temperature 800℃, applicable pH range 2-3 or 9-10.

- 254SMO, working temperature 1000℃, applicable pH range, lower than 3 or higher than 11.

- 1.4529, working temperature 1000℃, applicable pH range, lower than 2 or 10-11.

- C276, working temperature 1200℃, applicable pH range, lower than 1 or higher than 12.

Benefits

- Flue gas entering scrubbing area through tray is more even in gas/liquid distribution. This leads to uniform interaction between flue gas and limestone slurry, better absorption performance.

- Flue gas passing through tray openings will increase turbulence to enhance mass transfer and improve SO2 removal.

- Froth level on sieve tray leads to longer residence time of limestone slurry in absorption zone, and better SO2 & particulate capture.

- Support grid of scrubber tray can act as maintenenace platform during inspection and cleaning of spray nozzle.

- For FGD scrubber with given emission level, installation of tray means reduced power consumption, better alkali utilization, lower emissions.