Boiler tube shield

Product Details

Function

Boiler tubes work in harsh conditions. Inside, they need to bear high pressure and temperature of working medium. Outside, they have to withstand flue gas erosion, fly ash abrasion, sootblower cleaning pressure, high furnace temperature. All these could be potential reasons for tube leak that results in unscheduled shutdown. There are different ways to avoid that, but boiler tube shield is the most cost-effective precaution. It’s cheaper solution compared with replacement of damaged tubes, not to mention downtime and loss of power generation that comes with tube leak.

Erosion & abrasion doesn’t happen equally with all boiler tubes. Only tubes close to coal burner and soot blower, or windward tubes in specific areas have a higher chance with it. It’s about 20% of boiler heating surface. We can install boiler tube shield selectively in areas that are prone to occur tube leakage. Tube shield can protect boiler heating surface such as superheater, reheater, economizer, waterwall and extend service life to generate more avenue for plant owner.

Application

Boiler tube shield (also known as erosion shiled) is widely used in various types of boiler, mostly for power generation units. As protection layer covered on tube surface, it greatly slow down the progress of tube wall thickness reduction. Industries served include:

- Pulp and Paper

- Power Generation

- Heat Recovery Steam Generation (HRSG)

- Waste to Heat

- Petrochemical

- Sugar Mills

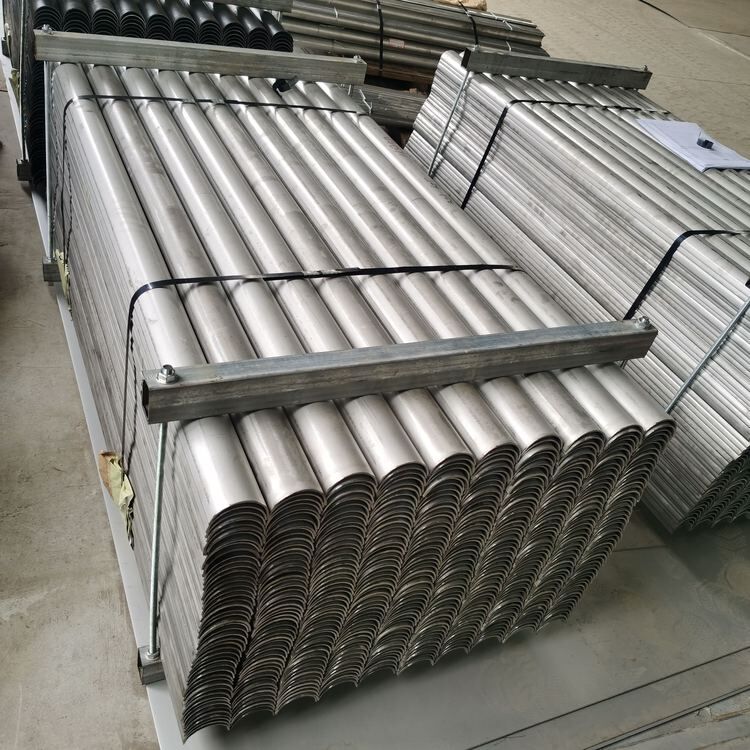

Types

- Curved tube shield (outside of bend, inside of bend)

- Straight tube shield

- S shape bend

- U Shape clip

- C Shape clip

Clip is used to hold tube shield in place by tackweld.

Material

Tube shield of different materials is available to match with working condition. The selection should be based on consideration of working temperature, mechanical properties, etc. The choice includes SS321 (1Cr18Ni9Ti), 309S (0Cr23Ni13, 1Cr20Ni14Si2), 310S (0Cr25NI20), 316L, 1Cr25Ni20Si2, 1Cr13, 1Cr6Si2Mo, etc. When 1Cr13, 1Cr6Si2Mo is choosed for low temperature superheater & reheater, working temperature should be lower than 600℃.

| Material | 1Cr18Ni9Ti | 0Cr23Ni13 | 1Cr20Ni14Si2 | 0Cr25Ni20 | 1Cr25Ni20Si2 |

|---|---|---|---|---|---|

| Max working temperature ℃ | 925 | 1095 | 1095 | 1150 | 1150 |

| Yield strength MPa | ≥205 | ≥205 | - | ≥205 | - |

| Tensile strength MPa | ≥520 | ≥520 | ≥590 | ≥520 | ≥540 |

| Elongation % | ≥40 | ≥40 | ≥40 | ≥40 | ≥35 |

| HB | ≤187 | ≤187 | - | ≤187 | - |

| HRB | ≤90 | ≤90 | - | ≤90 | - |

| HV | ≤200 | ≤200 | - | ≤200 | - |

Specification

Tube shield can be customized to suit any tube size. Common tube diameter is 32, 38, 42, 44.5, 48, 51, 57, 60, 63.5, 76, 89mm, etc. Most tube shield could cover 180°segment of tube surface. When used for membrane waterwall, it could be 120-160°. The most popular thickness is 2mm to 5mm.

Fabrication

Tube shield is produced by mould and press machine. For curved tube shield, bending machine is required. Our product is featured with good weldability, short delivery, smooth surface, beautiful outlook, etc.