Description

Benefits of flue gas cooler

Flue gas loss (q2), leading cause of heat loss in boiler, contributes about 60-70% of the total. It is mainly decided by flue gas temperature and volume. Normally when flue gas temperature increases every 12-15℃, q2 will increase 1%, accordingly, coal consumption will increase 1.2-2.4g/kW·h. Mostly, flue gas temperature in utility boiler is about 120-140℃, some are up to 160℃. Flue gas cooler could furtherly reduce temperature 40-50℃. The energy recovered from flue gas could be used to heat condensate water from low pressure feedwater heater, cycling water of district heating network, or combustion air for boiler.

When flue gas cooler is required?

- A plan to reduce flue gas loss q2.

- Air preheater alone can’t bring flue gas temperature to desired level.

- Too much cooling water is used to control flue gas temperature at FGD absorption tower inlet without using of gas gas heater.

- Air preheater is facing low temperature corrosion after various energy saving methods are put into operation, and air heater becomes necessary.

- Power plant economic is influenced by steam air heater.

Application

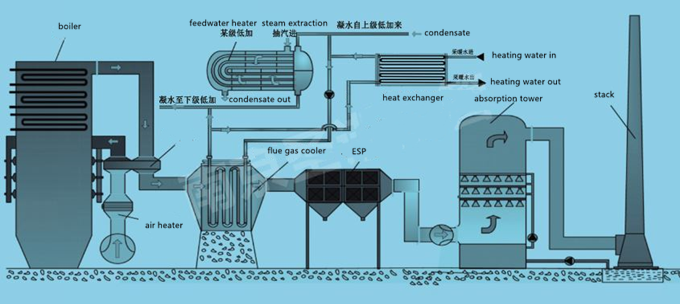

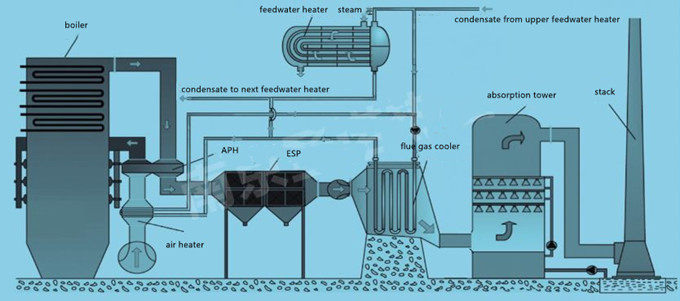

Heating condensate water from low pressure feedwater heater

Flue gas cooler could be connected with low pressure feedwater heater in parallel or series to reduce steam extraction from turbine, thus turbine output is increased. In parallel design, when flue gas cooler is in breakdown, the plant has to shut down. So, connection in series is popular.

Heating cycling water of district heating network

Some energy would be lost if flue gas is used to heat condensate water from feedwater heater, because saturated steam with increased pressure would conflict steam extracted from turbine. So, economic profit would be better if flue gas is used to heat cycling water. For CHP unit, it could heat cycling water in winter, and condensate water in summer.

Heating combustion air

Flue gas cooler could also transfer heat to combustion air. Increased temperature of combustion air means higher boiler efficiency. Flue gas for combustion air heating only is rarely seen in practice. Sometimes, it is combined with condensate water heating. This flexible design could adjust water flow according to season and boiler steam rate to optimize operation.

Location

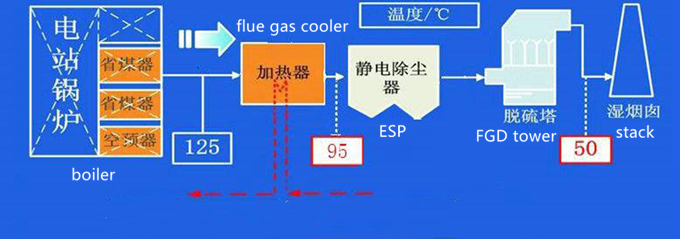

Before ESP

Flue gas cooler installed before ESP is an economic and easy operation. It could bring benefits like low fuel consumption, higher dust collection efficiency, less ID fan energy consumption, less water consumption in FGD system.

Before FGD absorption tower

Cooled flue gas at 85~90℃ could enter absorption tower directly. This design could utilize waste heat in flue gas deeply and reduce cooling water of FGD system.

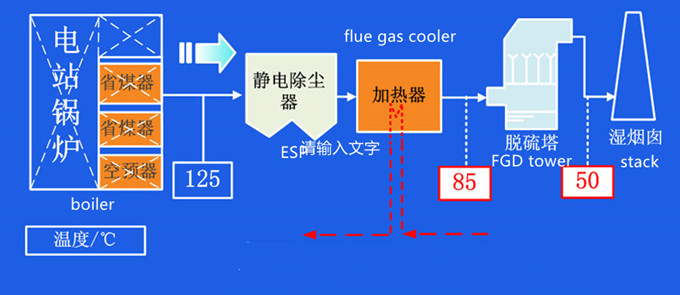

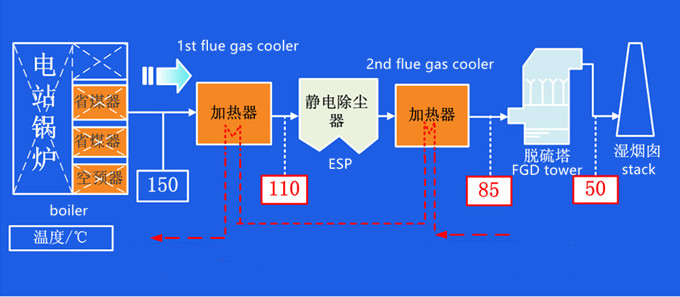

Two stage design

The first stage is placed before dust collector. Flue gas temperature is reduced to 115~125℃ to improve dust collection efficiency. For a hybrid particulate collector, it could extend service life of filter bags.

The second stage is placed before FGD absorption tower to utilize waste heat to the maximum.

Advantages

- Heat transfer element made of H fin tube is featured with high efficiency, compact size, rigid structure.

- Safe. Well designed system to make sure metal tube wall temperature higher than dew point.

- Acid resistant steel to withstand corrosion.

- Modular design, easy installation.