Steam desuperheater

Product Details

Steam desuperheater function

Steam desuperheater is a simple, however, cost-effective desuperheating device. Temperature reduction is done by direct contact between steam and cooling water. Evaporation of cooling water sprayed into steam takes excess heat from superheated steam and brings it to saturation temperature level. Desuperheater is widely used in CHP, power plant, textile, petrochemical, pharmaceutical, sugar refining, paper & pulp, etc.

Types of desuperheater

This direct contact desuperheater could be classified into: spray type or venturi type.

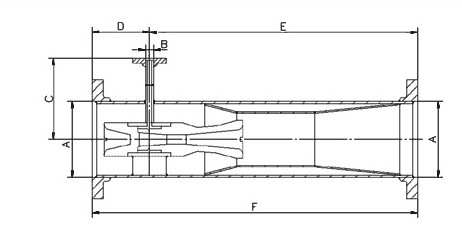

Venturi type desuperheater

Cooling water is injected at venturi throat area, and atomized by accelerated steam jet flow. It has two variations: one stage design or two stage design. For two stage venturi desuperheater, wet saturated steam from one stage would mix with superheated steam for second mixing. Due to negative pressure of jet flow and auxiliary mixing in first stage, two stage venturi desuperheater has a low pressure loss (< 0.05Mpa), it is suitable in cases where pressure difference between superheated steam and cooling water is small.

Working principle of spray type desuperheater

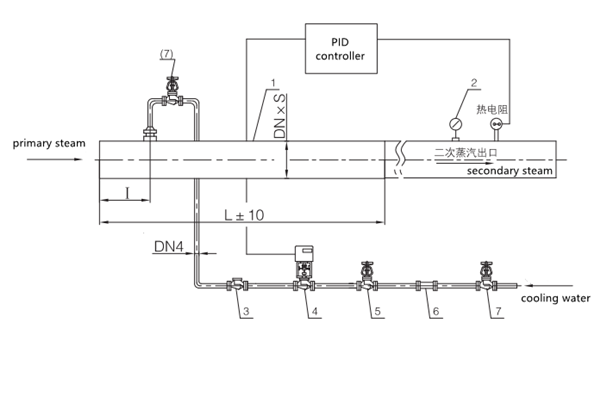

Steam desuperheating is a simple design. Spraying water into steam is the most popular way. A spray nozzle atomize and disperse cooling water into steam flow. Water is heated and vaporized, while steam is cooled down. Temperature transmitter, PID system and water control valve forms a closed loop for precise temperature control. Temperature transmitter sends signal to PID controller, which will then give instruction to valve actuator to adjust water amount in different conditions. Outlet temperature of steam is decided by the quantity of sprayed water. Desuperheater could produce a steam at saturation temperature (within 3℃).

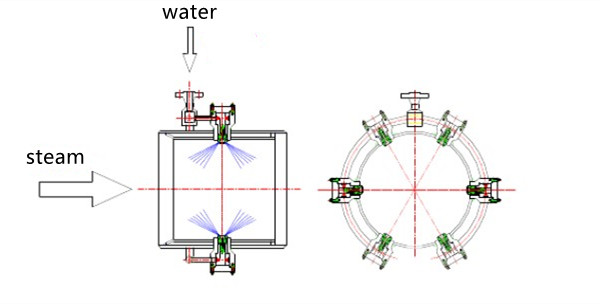

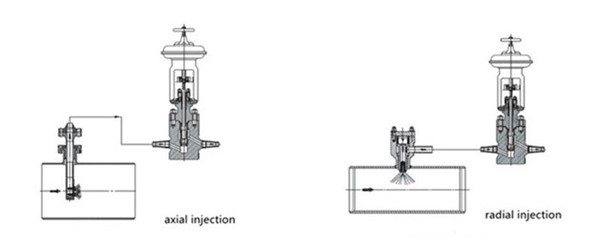

Spray type desuperheater usually has an inserted pipe fitted with single or multiple spray nozzle. The pipe can be radial or axial injection arrangement shown as below.

Radial injection desuperheater could be single point or multiple point.

Cooling water

As water and steam is mixed directly, total dissolved solids in cooling water should be minimized to the lowest level. Or else, the contaminants would deposit on valve surface, holes of spray nozzle, inner wall of downstream pipes. A strainer before control valve is necessary to control water quality. Injection water that has a temperature close to saturation is preferred in desuperheating system for the following reason. Normally, boiler feedwater is used as cooling medium for attemperation by its latent heat when vaporized into steam.

- Minimize suspension time of water particles in steam.

- Avoid water falls to the inside of pipe work by a fast evaporation.

- A less opportunity of condensate inside pipes.

Spray nozzle

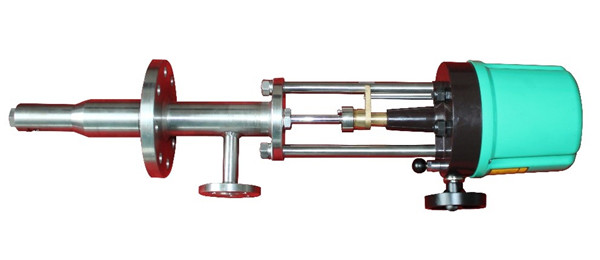

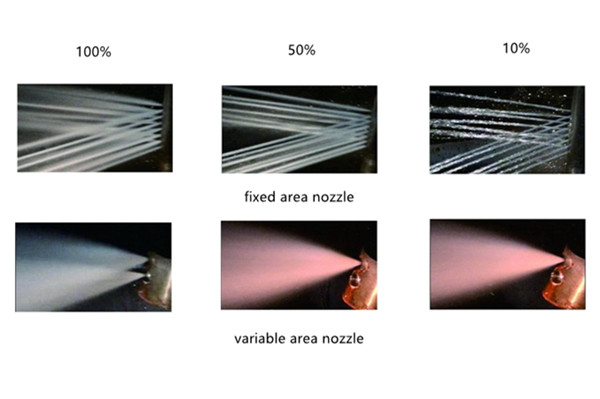

In some cases, working conditions would vary along with time, then cooling water dispersion is an important design to consider. Spray nozzle with fixed area is no longer suitable. Cooling water amount is changed by control valve. When water amount changes, water speed is changed along with it. Atomization performance is bad when water speed is low for a spray nozzle with fixed area. That would result in obvious increase of drain water. This situation greatly restricts operation flexibility to thermal load variation.

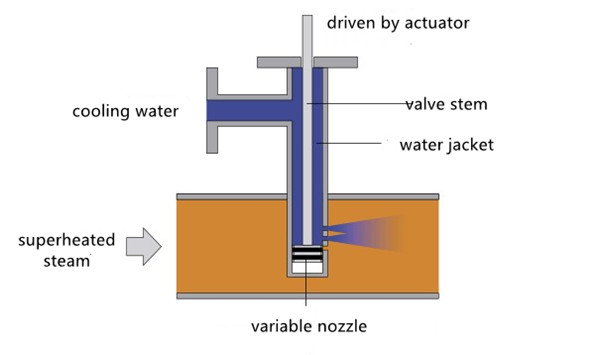

Spray nozzle with variable orifice is invented to solve this problem. When water amount changes, spray nozzle could vary its area to optimize water speed for ideal atomizing performance.

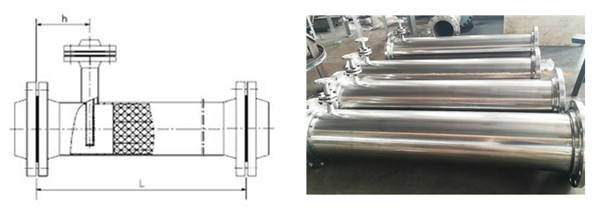

Thermal sleeve

If water particles fall onto inner wall of desuperheater pipes, it would cause thermal stress, sometimes even cracking. To avoid this, a thermal sleeve is installed inside. The length of thermal sleeve should ensure sprayed water is all vaporized before they move out of it.

What is desuperheater turndown ratio?

Variation of steam inlet temperature, pressure, flowrate would require different amount of cooling water. Turndown ratio is a specific value between max flowrate and min flowrate. Steam turndown ratio describes the range of steam that it can desuperheat. Cooling water turndown ratio describes amount of water that would be required.

Benefits of desuperheater:

- Simple structure, reliable performance.

- Excellent atomization performance.

- Sleeve inside casing to avoid thermal shock.

- Accurate control, 3℃ within saturation temperature.

- Easy installation & maintenance.