Expansion joint

Product Details

Expansion joint is flexible metallic/rubber/fabric components designed to maintain piping system or protect equipment. It gets widely used in power generation, steel, oil & gas, chemical, metallurgy, environment protection industry for the following function:

- Absorb displacement induced by thermal expansion & contraction.

- Absorb movement caused by ground settling and seismic activity.

- Compensate deviation during installation.

- Balance internal pressure to relieve stress applied to anchor.

- Sound attenuation by absorption of flexible material.

- Absorb equipment vibration and minimize damage to duct.

Various expansion joints can be found in flue gas, combustion air, water, coal pipes in power plant. Below are some introductions for different applications.

Tied universal bellow assembly (MSW type) for pulverized coal pipe

This metallic expansion joint is specially designed for pulverized coal feeding pipe to allow axial, lateral or angular movement. It is suitable with two-phase fluid like hot primary air and exhaust air from coal pulverizing system. Joint bellow is fabricated with stainless steel SS321 or 304 by hydroforming process. To improve wear resistance and service life of expansion joint, internal liner with increased thickness is built together with adaptor tube.

Features:

- No leakage & deposit of pulverized coal.

- Good flexibility to allow free expansion of boiler & piping system.

- Easy installation & maintenance.

- Long service life.

Pressure balanced elbow assembly for BFPT exhaust steam pipe

Exhaust steam pipe between boiler feed pump turbine (BFPT) and condenser is short in length, but large in diameter. An expansion joint is necessary to absorb movement and avoid huge counter-force. Pressure balanced elbow assembly could absorb movement in any direction, and as its name implies, balance internal pressure. Now it has been successfully used in 300, 600, 1000MW units.

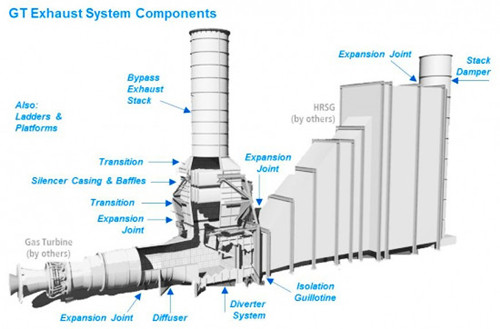

Fabric expansion joint for gas turbine, bypass, HRSG

Flue gas discharged from gas turbine could be 485-650℃. Flue duct has a big thermal expansion in hot status. Fabric expansion joints are installed to absorb axial, lateral and angular movement to avoid accidents. Install locations include GT outlet, diverter damper outlet to bypass stack, diverter damper outlet to HRSG.

Expansion joint for air cooled condenser exhaust steam pipe

This expansion joint has single & double hinge design. Hinge structure could bear thrust by external or internal pressure. Single hinge design could absorb movement in single plane only, while double hinge design could compensate angular displacement in any plane.

Expansion joint for district heating pipeline

For heating network piping, different expansion joints could be used: bellow type, sleeve type, ball type.

Below is a bellow type expansion joint specially designed for direct buried pipe. Its size ranges from DN32 to DN4000 with working pressure 0.6-2.5Mpa. Carbon steel, cast iron, stainless steel is suitable for fabrication to meet with specific requirement. Due to flexural strength given by rigid structure, it can ignore influence caused by pipeline settlement. Under the protection of casing pipe and guide pipe, bellow element can freely absorb axial movement. It can serve more than 30 years without maintenance.

For overhead pipeline, ball type expansion joint is used in most cases.

Metallic expansion joint for flue gas & combustion air & pulverized coal pipeline

Fabric expansion joint for flue gas & combustion air & FGD pipeline

Fabric expansion joint is widely used in power plants due to following advantages:

- Better compensation. It provides much more compensation to axial, lateral and angular movement than metallic expansion joint in a small space.

- No resistance caused by deformation. Compensation element of fabric expansion joint is made of soft materials like glass fiber, PTFE plastic, rubber, etc. Compared with metallic expansion joint, it eliminates stiff transfer of stress. Usage of huge and heavy anchors in pipeline is avoided.

- Excellent resistant to corrosion. Usage of fluoroplastic and organosilicone material brings fabric expansion joint great performance in FGD system.

- Sound and vibration isolation. Fibrous material could obviously reduce noise and vibration of boiler, fan, pipeline, etc.

- High temperature resistance up to 1000℃.

- Less weight, easy installation.

Rubber expansion joint for water pipeline

Rubber expansion joint is used for the transfer of boiler feedwater, cooling water, condensate water in thermal power plants.