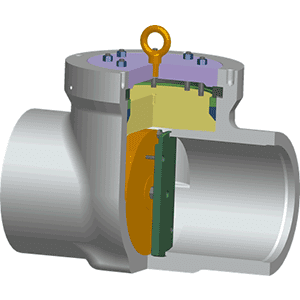

Hydrostatic test isolating valve

Product Details

Application

Hydrostatic test is done to boiler high pressure components before boiler produces steam to ensure the integrity of superheater and reheater system. An isolating valve is installed at the outlet of superheater, inlet & outlet of reheater to provide isolation during the test.

a. in isolating state b. in normal state

Features

- Highly reliable pressure seal bonnet. The higher pressure is applied to bonnet, the more reliable the seal becomes.

- U shape groove at both ends. Joint with piping system directly by welding is enough.

- Top entry design, low pressure drop. Seal closure could be taken out after test is finished, isolating valve is used as a part of piping system. Then there is no need to cut off this isolation device. This design allows smooth flow without obstructed passage. And a guide cylinder is put into place of seal closure to minimize pressure drop.

- Adjustable jacking stud presses bonnet against reinforced sealing held by segmented retaining ring, which is treated specially to enhance properties.

- O shape sealing ring, valve seat cladded with SS.

- High reliability, minimum maintenance.

Technical data

Standard: ASME B16.34

Size: DN200~DN1200

Pressure: 6.3-76MPa

Temperature: 29℃~650℃

Fabrication: by casting or forging

Suitable medium: water or steam

Material

1、WCB、ZG20CrMo、Cr5Mo、ZG20CrMov、ZG15Cr1MoV

2、25#、12Cr1MoV

3、ASTM A216 WCB、 ASTM A217 WC6、 ASTM A217 WC9、 ASTM A217 C12A

4、ASTM A105、ASTM A182 F11、ASTM A182 F22、 ASTM A182 F91、A182 F92

Isolating valve supplied by Geckointech has proven performance in 600MW, 1000MW units. It is a low cost but effective isolation device for boiler hydrostatic test.