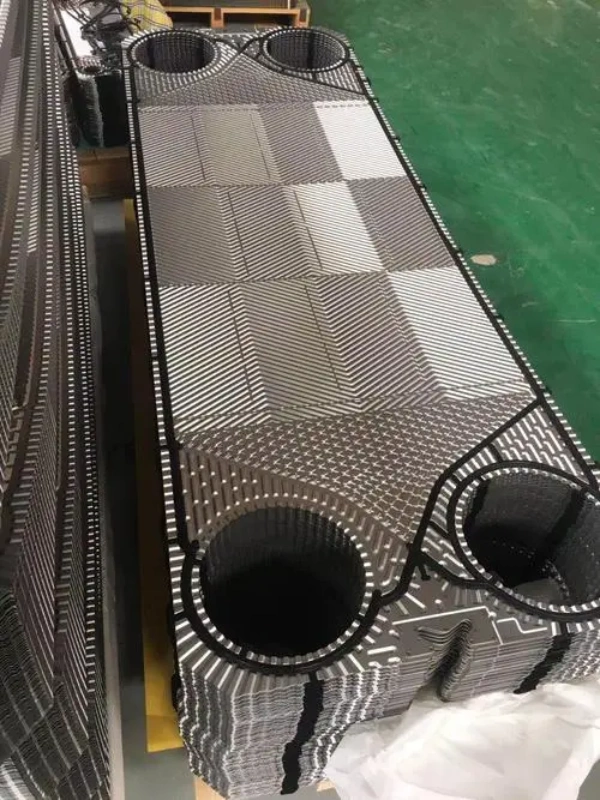

Heat exchanger gaskets

Product Details

Introduction

Featured with high heat transfer efficiency, compact structure, small footprint, easy installation & maintenance, plate heat exchanger has wide applications in industry: power generation, oil, chemical, metallurgy, food, dairy, beverage, pharmacy, textile, paper making, HVAC, etc. As an experienced heat exchanger plates and gaskets supplier, we can supply OEM parts for famous brands of plate heat exchanger in the world.

Sealing gaskets are vital parts for plate heat exchanger for following reasons:

- PHE gasket service life influence maintenance frequency of plate heat exchanger.

- Fluids run through heat exchanger. Gaskets act as sealing strips between plates to prevent leakage into atmosphere.

- Prevent mixing between hot/cold fluids.

Corrosive fluids, working temperature & pressure demand high quality gaskets to ensure desired heat transfer. So application scope of plate heat exchanger is greatly restricted by gaskets.

Heat exchanger gasket supplier

Engaged in PHE gaskets, we have supplied millions of pieces to match with heat exchangers made by famous brands like APV, GEA, HISAKA, SWEP, SONDEX, TRANTER, etc. We have in-house measurement to delivery a perfect piece of sealing strip.

- Raw material purchased from leading manufacturer ensures excellent quality, high stability, long service life.

- Advanced testing method and equipment according to international standards.

- Physical property and compression set of gaskets can meet with international standards.

- High precision gasket mould for Alfa Laval, GEA, Tranter, Sondex, APV, Funke, Vicarb, etc. Gasket dimension, thickness, hardness to the same level with Gislaved.

- Excellent properties. Compression set is 10% lower than national standard. Better sealing performance, longer service life, higher pressure, etc.

Heat exchanger gasket types

There are many rubbers for production of PHE gasket. Correct selection of gaskets is a result after consideration of cost, service life, applicable temperature & pressure & fluids comprehensively.

| Gasket material | Working temperature (℃) | Applicable fluid |

| NBR | -15 to 120 | Seawater, brine, mineral oil, etc. |

| HNBR | -15 to 140 | High temperature oil, water, etc. |

| EPDM | -25 to 150 | Hot water, steam, milk, beverage, acid, alkali, etc. |

| VITON/FKM | -5 to 180 | Acid, alkali, etc. |

Available brand and model

| HISAKA | |||||||

|---|---|---|---|---|---|---|---|

| LX10 | LX20 | LX30 | LX40 | LX025A | LX095A | LX125B | LX195B |

| LX40A | LX50A | LX515A | RX10A | RX11A | RX13A | RX30 | RX135A |

| RX185A | RX326A | RX595A | RX595B | RX596B | RX625A | RX715 | RX70 |

| RX725A | RX795 | UX10 | UX115 | UX125 | UX20 | UX226 | UX228 |

| UX398A | UX30 | UX40 | UX416 | UX80 | UX90 | UX925 | UX995 |

| UX997 | UX100 | UX130 | SX40 | SX41 | SX43 | RX90 | RX13A |

| SX90 | EX2 | UX01 | RX100A | RX31A/B | |||

| API | |||||||

|---|---|---|---|---|---|---|---|

| SigmaM7 | SigmaM9 | SigmaM13 | SigmaM19 | SigmaM25 | SigmaM26 | SigmaM27 | SigmaM35 |

| SigmaM36 | SigmaM37 | SigmaM55 | SigmaM56 | SigmaM66 | SigmaM76 | SigmaM96 | SigmaM106 |

| SigmaM156 | SigmaX25 | SigmaX35 | SigmaX55 | Sigma22 | Sigma48 | Sigma49 | Sigma64 |

| Sigma85 | Sigma108 | Sigma114 | Star45 | Star90 | Star150 | ||

For more details, welcome to contact with us.