Fly ash sampler

Product Details

Overview

Carbon in ash is an important indicator that reflects combustion efficiency of coal fired boiler. Reasonable control of unburned carbon level is beneficial to reduce heat loss caused by incomplete combustion. In other words, lower loss on ignition means less “wasted” fuel. Fly ash sampling and analysis helps operators to keep close eye on fuel utilization. With analysis result, plant staff can fine tune pulverizing system and draft system accordingly.

For an accurate analysis, interference factors such as the existence of moisture, hydrated lime, ammonia and calcium carbonate may bring negative affect on result. So design and execution of sampling procedure must be accomplished with great attention. But the first and important step is how to collect representative fly ash samples. Our isokinetic fly ash sampler is guarantee for that.

Structure

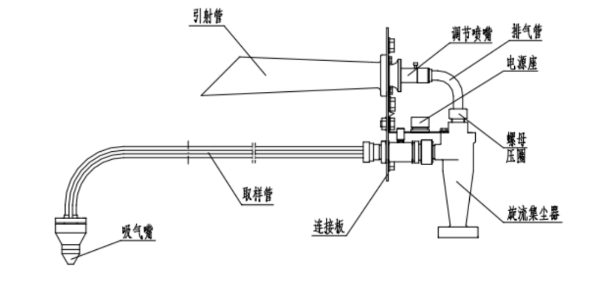

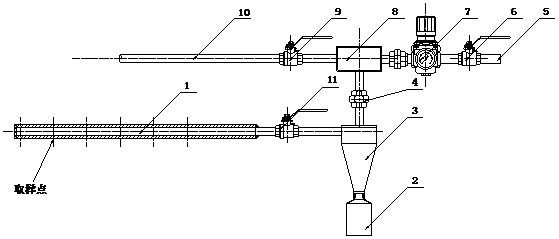

Fly ash sampler is made up of following parts: nozzle tip, probe, ejector, cyclone, regulating nozzle, ash bottle, install plate, etc.

Due to its unique design and structure, fly ash sampler can do isokinetic sampling regardless of flue gas velocity changes. Representative samples drawn from boiler back-pass is the warranty for reliability of analysis.

Working principle

Due to vacuum created by ejector, automatic fly ash sampler would draw airborne particles through nozzle tip from flue pass. Cyclone will separate fly ash and store them in bottle, while clean gas is turned back to flue pass through Venturi tube. Regulating nozzle can manipulate pressure to ensure isokinetic sampling.

Also, we develop new type of fly ash sampler with positive pressure purging function. It could not only clean the probe and cyclone by compressed air to avoid clogging, but also drive ejector to establish vacuum when flue gas is positive inside duct.

Features & Benefits

- Minimize unburned carbon level to reduce fuel consumption.

- No need for external power to operate.

- Bring fly ash quality to higher level for cement industry.

- Online sampling gives in time feedback compared with sampling from ash hopper.

- Reduce labor work involved in manual sampling.