ESP electrode

Product Details

ESP electrode introduction

ESP electrode is core part of electrostatic precipitator. ESP power supply imparts high voltage electric field to collecting electrode and discharge electrode to make dust particles electrically charged.

Material

ESP electrode is fabricated with different materials for various performance.

Stainless steel: 1.4529, 316L, 304, 818, 2205, 201, etc.

Alloy: Titanium TA2 alloy, lead-antimony alloy, C276

Carbon steel: SPCC

Discharge electrode

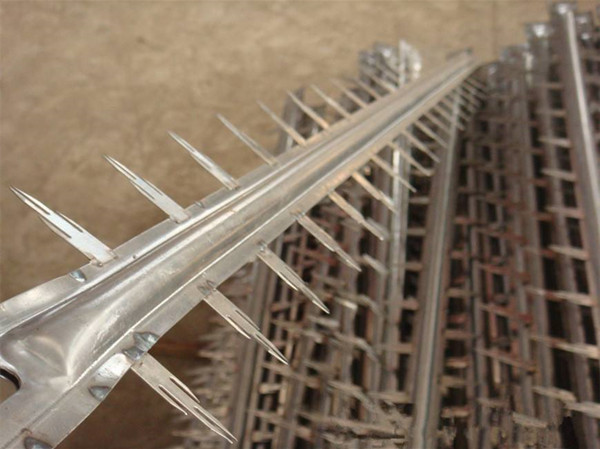

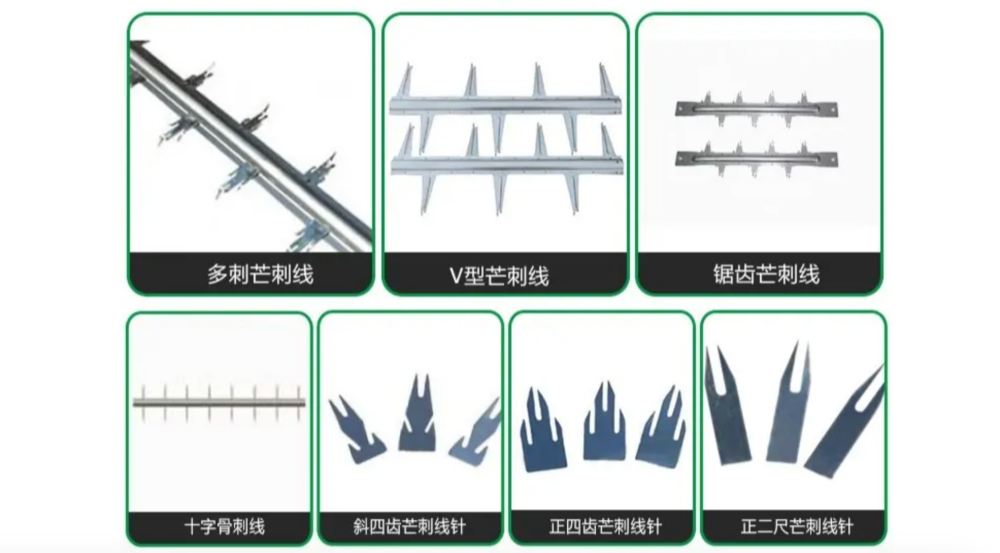

Discharge electrode is also called discharge wire, emitting electrode. It is connected with negative polarity of power supply. Corona discharge will be generated around spike of discharge electrode. And corona power is closely related with spike curvature.

Discharge electrode should have good mechanical strength to keep its shape in hot condition. Rigid frame must be used to support discharge electrode. As shown in photo, there are different designs of discharge electrode: RS type, BS type, cross type, V type, spiral type, sawtooth type, spiral type, etc.

Collecting electrode

Collecting electrode or collecting plate (different design C480, z385, c390, ZT24, W) is made of sheet metal. Particles are collected on its surface. Good collecting electrode should have the following features:

- Even distribution of electric field on electrode surface.

- Good rigidity, low deformation under hot temperature.

- Good transmit of rapping forces to keep it clean.

- Dust caked on metal plate should fall down in clumps or pieces to avoid secondary fugitive dust.

- Not easy to creat flashover with discharge electrode.

When dust particles deposit on DE surface, corona power is weakened. And back corona phenomenon will occur when particles deposit on CE surface. A rapping system is required to keep ESP electrode clean.

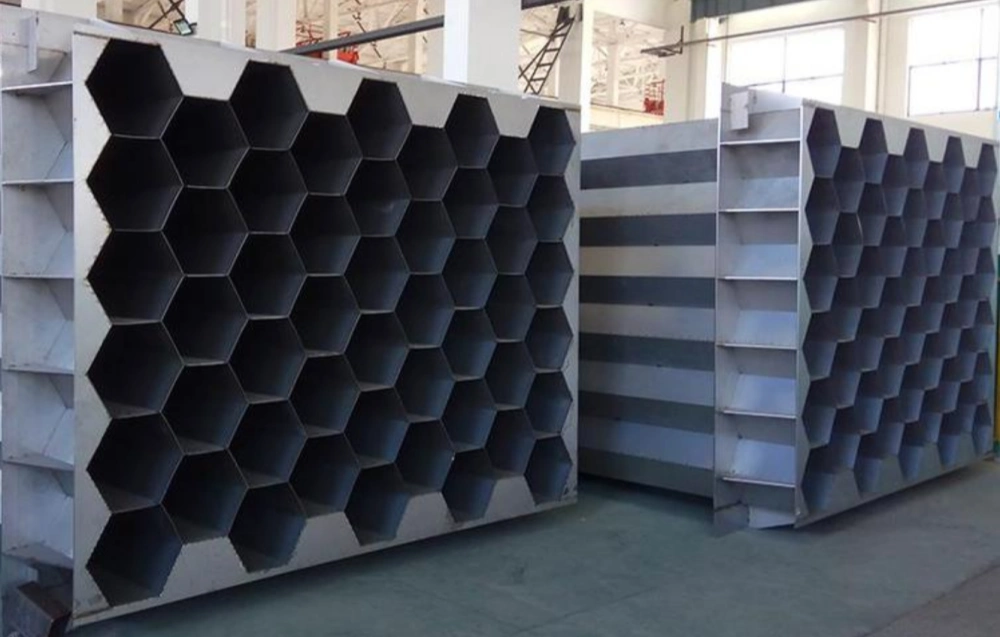

Tubular collecting electrode for wet ESP

ESP electrode design varies in different cases to achieve best filtration performance. We can customize different shape and specification according to client’s requirement.