Ceramic balls for ball mill

Category Coal pulverizing system

Product Details

High alumina ceramic balls for ball mill grinding purpose are made through batching, pulverizing, slurrying, molding, drying, firing process. Ceramic balls are white color, spherical shape with diameter 0.5-120mm.

Ceramic balls has properties like high strength, high hardness, wearing resistance, high temperature resistance, corrosion resistance, pollution free for product quality. Ceramic balls as grinding medium are widely used for ball mill in cement plant, power plant, glass works, steel works, chemical plant, etc. Its grinding ability and wearing resistance is much better than pebble.

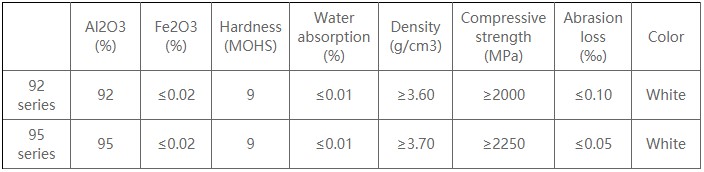

Ceramic balls technical data

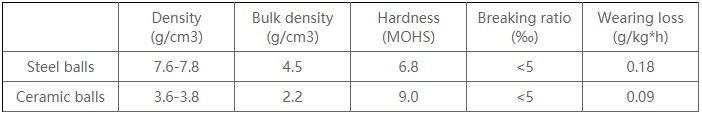

Ceramic balls VS steel balls

Benefits of ceramic balls

- Reduce power consumption. Many practices prove ceramic balls could reduce 20% loading weight, motor current is reduced 20% or higher, power consumption is reduced 15% per tons of cement.

- Reduce noise & temperature inside ball mill.

- Wearing loss is only 50% of steel balls.

- Improve grinding efficiency & cement property. Particle size distribution becomes more reasonable. Content of particles of 3-32μm is improved by 2%. Water consumption to achieve normal consistency is reduced by 1-2%. Cement will have better suitability for additives.

- Pollution free. Easy to meet with national standard for water soluble Cr+6 (≤10mg/kg).