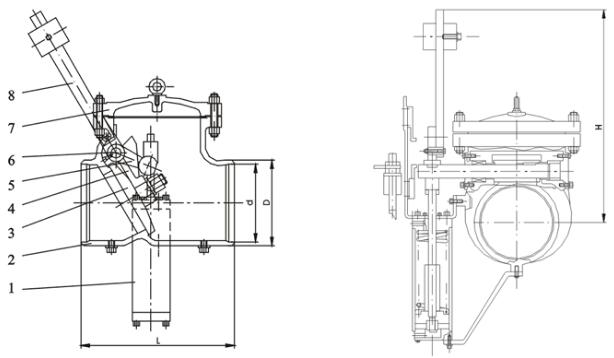

Steam extraction check valve

Category Valve

Product Details

Application

Steam extraction check valve (H664Y) is installed on turbine extraction lines to prevent reverse flow of steam or water. It protects turbine from following accidents by quick and tight closure within 0.5 second.

- In load rejection event, pressure inside turbine drops rapidly, backflow of steam from feedwater heater and process line would cause overspeed failure.

- When water level inside feedwater heater is out of control, water induction into turbine could damage equipment in several ways.

Feature

- Bolted bonnet designed for easy maintenance of internal parts.

- No jamming, free swing valve disc to minimize pressure drop.

- Tilting valve disc with minimum travel to ensure quick closing.

- Self aligning disc to ensure tight closing with sealing surface.

- Disc and seat are cladded with Cr13 series SS or Cobalt base alloy to improve wearing resistance.

- For check valve installed on extraction lines with large diameter, external counterweight is used to balance mass of disc. It greatly reduce the torque required to open the valve.

- Steam extraction check valve could operate with its own gravity weight, or equipped with pneumatic or hydraulic actuator as an aid. Pneumatic or hydraulic cylinder could be coated with abrasion resistant layer inside to reduce operation resistance. Actuator is equipped with opening/closing position signal output & local indicator.

Specification

Standard: ASME/ANSIB16.34

Connection: butt weld or flange

Pressure: PN16~PN420

Size: DN80~1000

Material

1、WCB

2、ZG20CrMo、ZG15Cr1Mo1V

3、ASTM A216 WCB

4、ASTM A217 WC6、ASTM A217 WC9

Temperature:

1、WCB:-29℃~425℃

2、Alloy steel:-29℃-540℃、-29℃-570℃